Abstract

This study aims at understanding the business environment of aircraft maintenance company Abu Dhabi Aircraft Technologies (ADAT) and identifying the factors leading to a strategic change to the organisation and the impact of those factors on the performance of the organisation. The research objectives of this study were to analyse the strategic business environment of ADAT, to investigate the strategic change process company, to study the impact of the strategic change on the company and to identify the ways to improve performance of the company.

To investigate the research question a combination of secondary and primary research methodology was used. The secondary data was obtained from the already published data and the primary data was obtained through questionnaires by conducting a survey. Total 137 employees of ADAT participated in the research study however, only 96 questionnaires appeared to be completely filled. The data has been analysed by using the descriptive statistical techniques. The findings of the research suggest that efficient services of aircraft maintenance companies require resources and technical expertise. It has been identified that employee turnover has been one of the major issues of the company which directly influenced the performance of the company as a result of strategic change. Therefore, to increase the performance company needs to adopt strategies that can help it to gain sustainable growth in the industry by increasing its ability to retain highly-qualified staff and reducing costs of recruitment and selection. Based on the analysis, a few recommendations have been also given to the company.

Table of Contents

- Abstract

- List of Figures

- List of Tables

- Introduction

- Research Background

- Organisation Profile: Abu Dhabi Aircraft Technologies (ADAT)

- Research Aim

- Research Objectives

- Research Questions

- Research Rationale

- Research Significance

- Research Limitations

- Definition of Terms and Abbreviations

- Structure of Dissertation

- Literature Review

- Aircraft Maintenance

- Financial, Auditing and Pricing

- Human Resource Management

- Marketing and Communication

- Conceptual Framework

- Research Methodology

- Overview on Research Questions

- Overview of Literature Review

- Research Design

- Research Methods

- Secondary Research

- Primary Research

- Data Collection Tool

- Sampling

- Data Collection Procedure

- Validity

- Ethical Considerations

- Findings and Analysis

- Findings of Secondary Research

- Findings of Primary Research

- Conclusion and Recommendations

- Recommendations

- Reference

- Appendix

List of Figures

- Figure 1 Business environment of Aircraft Business

- Figure 2 Facility Map

- Figure 3 Conceptual Framework

- Figure 4 Expenditure of the Emirates

- Figure 5 Experience

- Figure 6 Associated with particular zone

- Figure 7 Respondents’ Association Zones

- Figure 8 Involvement of Respondents in Maintenance Activities.

- Figure 9 Number of People Working in Aircraft Zone

- Figure 10 Percent of Technical People in Aircraft Zone

- Figure 11 Ranking of Organization for Maintenance Services

- Figure 12 Perception of Employees

- Figure 13 Performance of the Organization

- Figure 14 Role of Training

- Figure 15 Overall efficiency of the organization can be Improved

- Figure 16 To improve efficiency in the Present scenario

List of Tables

- Table 1 Employee Turnover from 2008-2010

- Table 2 Turnover Ratio 2008-2010

- Table 3 Total Employee Replacement cost from 2008 -2010

Introduction

Research Background

The global airline industry has net value of $467 billion which is expected to reach nearly $609 billion by 2013. The growth in the airline industry was nearly 30.4% in 2008 and growth in the global airline market was 1.8% by volume. It is expected to increase by 23.6% of the volume till 2013. There are tremendous changes observed in various factors of airline industry. Due to privatisation and entry of private players, the competition of the airline sector across various destinations of the world has increased. The airline companies have increased the range of services by offering economic to business class travelling, improving frequency of flights, targeting more geographical coverage and enhancing operational efficiencies of the airlines.

This is a known fact that airline industry is one of the most expensive and technology-intensive industries. The business environment of airline sector is very complex. The airlines are not just concerned about covering the destination in shortest possible time of all the available transportation facilities but they are also concerned about providing safety. This requires aircrafts to be in excellent operational condition. Therefore, aircraft maintenance activities are one of the most important activities for the airlines and companies are investing heavily on the maintenance related activities.

“Each generation of airplanes requires many years from concept to deployment—for military aircraft, it may take two to three decades. It is common for suppliers to aircraft manufacturers and airlines to earn significantly better profit margins. The customer for airline service is, in general, most concerned about the price of flights, with secondary concerns of convenience and com fort. Consequently, manufacturers focus on affordability, efficiency, and reliability” (Basole and Rouse, 2008: 61)

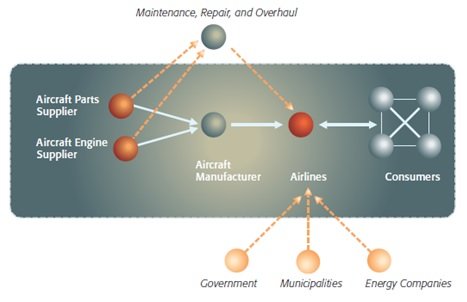

The primary factors affecting airline business are aircraft parts’ suppliers, aircraft engine supplier, aircraft manufacturer, government, municipalities, energy companies and consumers (Figure 1).

According to IATA (2010) the estimated expenditure on the aircraft maintenance is nearly $45.2 billion. In 2009, the average maintenance costs expressed in dollar per flight hour was $1095, dollar per cycle was $2648 or dollar per aircraft was $3.4m. The maintenance expenditure is usually 10-15% of the total operational costs.

Figure 1 Business environment of Aircraft Business

Source: Basole and Rouse (2008:60)

Every aircraft is subjected to various levels of maintenance. Maintenance is done before and after every flight and each pilot ensures that proper repairing and maintenance activities have been performed before flying any aircraft. The maintenance activities of aircraft refers to all those actions that help restoring the aircraft to a serviceable condition like repairs, modifications, overhauling, servicing, inspection of parts and the entire aircraft. This helps in identifying serious conditions, failures and defects. These factors help in determining the condition of aircraft and its ability to fly without any potential risks.

There are various critical factors that determine success of an airline (McCabe, 2010). These success factors are assessed through different analytical tools. These analytical tools help in evaluating the business environment of the company. According to Thompson, Strickland, & Gamble (2005) one of the reasons of companies trying to expand to the foreign markets is rivalry within the domestic market. The expansion to foreign markets helps companies to increase their revenue. The intensity of the key success factors varies from industry to industry. Competitiveness, customers, management of people, fleet and financial position of a company are the key factors for the competitive success of an airline company (McCabe, 2010).

In the case of aircraft maintenance service providers, there are very limited service providers that make the competitive positions for the existing companies strong. These companies provide business to business services. The overall approach for the maintenance service providers is based on industrial marketing and service marketing factors. Highly technical and specialised services of aircraft maintenance companies make these services very unique and limited to aircraft industry. The entry and exit barriers for such companies are always high.

The available literature for the aircraft maintenance is very limited. This has been one of the low research areas in the business management. The researches conducted so far have been highly technical. However the information is available from different sources in the form of news, industry analysis reports, press release of the companies and most importantly the company websites. The aircraft maintenance is a critical aspect of the airline business because it leads to safety which is the primary concern for the airline companies and regulatory bodies. Due to this fact, maintenance is the integral and important part of airlines’ operations. The maintenance activities are conducted on the basis of certain operational factors. These activities can be conducted periodically based on duration of flying or flight hours, flight cycles or days of operations. The flying hours are the most popular parameter for determining the maintenance requirement of an aircraft. There are some level checks like A-check, B-check, C-check and D-check. A-checks are the daily routine checks whereas C and D are the heavy maintenance checks. C and D checks are conducted after every four to five years of operations.

The people involved in the heavy maintenance process have diverse background. The maintenance personnel are mostly from technical and engineering background.

The heavy maintenance activities are considered as high-cost activities. The aircraft maintenance cost has been a major concern for the airline industry. The companies are trying to find out ways through which they can minimise the labour cost and the cost of no-flying hours. These are the overhauling processes for the aircraft that make it ready for operations like a new aircraft and the flying hours start with zero. During the heavy maintenance work, the aircraft is pulled out from the revenue generation process for more than 15000 flying hours or four to five months.

“These major checks require intense pre-planning by using effective manpower and resources to the most efficient level. Failure can cause wastage and loss of valuable revenue services.” (Emirates website, 2009)

Organization Profile: Abu Dhabi Aircraft Technologies (ADAT)

ADAT is the member of a strategic investment development vehicle, Mubadala Development Company, which is completely owned by Abu Dhabi government. ADAT provides highly technical aircraft maintenance services to the commercial and military aviation industries. The company was launched in 2007. The foundation of the company was transformation of the Gulf Aircraft Maintenance which provided it heritage of world-class maintenance, repair and overhauling expertise (ADAT, 2010).

It provides airframe services, component services, engine services, material management and supply, technical services and technical training.

“AMMROC (Advanced Military Maintenance, Repair and Overhaul Center) LLC. is a dedicated military Maintenance, Repair and Overhaul (MRO) centre formed to deliver a wide range of aircraft maintenance and support services to the United Arab Emirates (UAE) Armed Forces and other military operators throughout the Middle East and North Africa region.” (ADAT, 2010)

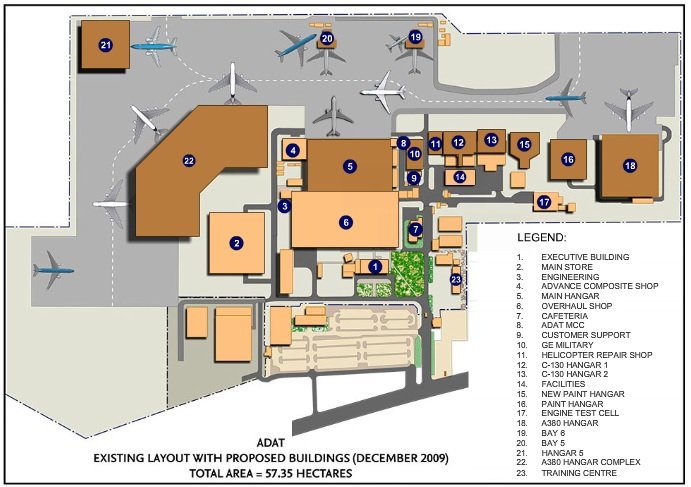

The organisation has robust infrastructure which includes Aircraft hangers’ cover of nearly 42,000 m2. There is 140,000 m2 parking area. This area is utilised for light maintenance activities. It is planned that by 2012 there will be fully dedicated light maintenance facility.

“supported by an extensive range of component and engine overhaul and repair workshops, test laboratories and bonded storage, as well as a 100,000lb thrust Engine Test Cell, totalling 57.35 hectare of facilities.”

Hangers provide a state of the art single bay A380 hanger. This is first of its kind facility. Hangers’ facilities available are four bay A300/767, A330/A340-340 size paint hangar, A340 size paint hangar, military helicopter maintenance hangar, two bay military C130 hangar and B777/A340-600 maintenance hanger. (ADAT, 2010)

There are line stations that operate at 6 major airports of Middle East. These airports are Abu Dhabi International, Sharjah International, RAK International, Al Ain International, Al Bateen Airbase and Al Minhad Airbase.

Figure 2 Facility Map

Research Aim

The rapidly changing business environment influence the aircraft maintenance companies like other businesses. However, being highly-technology-based organisations, these companies do not give much focus in identify the factors leading to strategic change to the company and how it can influence the organisation. The aim of this report is to investigate how a strategic change influences the performance of the organisation and what strategies companies need to adopt to improve its performance after the strategic change.

Research Objectives

Objectives

The primary objective of this research study is to investigate the strategic change at Abu Dhabi Aircraft Technologies (ADAT) and identifying the ways through which performance could be improved in this aircraft maintenance company. The other objectives of this research study which need to be fulfilled include:

- To analyse the current business strategy of ADAT and the nature of the competitive business environment of Abu Dhabi Aircraft Technologies (ADAT)

- To identify a range of strategic options open to Abu Dhabi Aircraft Technologies (ADAT)

- To evaluate how strategic change has affected the performance of the aircraft maintenance company

- To identify how aircraft maintenance companies can improve their performance

Research Questions

- What is the strategic business environment for Abu Dhabi Aircraft Technologies (ADAT) and the nature of competition faced by the company?

- How the strategic change in an aircraft maintenance company like ADAT influences the performance of the organisation?

- What are the ways through which Abu Dhabi Aircraft Technologies (ADAT) can improve its performance to sustain and grow in the current business environment?

Research Rationale

There are limited studies conducted in the past to understand the significance and strategic advantage of the aircraft maintenance activities. In the case of companies like Abu Dhabi Aircraft Technologies (ADAT) where the services offered by the company are exclusively for the aircraft companies, studies are very limited. Companies like ADAT operate in a highly technical and complex business environment which increases uncertainty for these companies. The business to business environment is very vulnerable where volume of the customers is low and value of each customer is very high. This research will help understanding the business environment of ADAT and develop recommendations on the basis of the existing business environment.

Research Significance

This research covers various aspects of a business to business environment in aviation industry from the service providers’ perspective. The research helps in understanding the various key variables of the business environment and identifying the strategic business issues. The research also helps in developing strategies that can help the organisation to re-evaluate its existing strategies to gain competitive advantage.

Research Limitations

The information available for the study was limited. There are various aspects of the internal environment of the business that could have been evaluated and understood. Another limitation of this research study is the sample size. The sample size of the research is very small and a large sample size could enhance the reliability of the research. Third, the case study approach has been used as the research methodology which reduces the implications of this research in its industry only. Although it appears to be a limitation of this researcher however, the aim of this research was to keep the focus on aircraft Maintenance Company only because of the lack of research in this area.

Moreover, various primary and secondary resources have been used to investigate all the research questions and to achieve research objectives, which enhance the significance of this research as a good academic research study.

Definition of Terms and Abbreviations

- ASK: Available Seat Kilometres (Overall Capacity)

- ATK: Available Tonne Kilometres

- FTK: Freight Tonne Kilometres

- PTF: Passenger to Cargo aircraft conversions

- PCN: Personnel Certifications in Non-Destructive Testing

- RPK: Revenue Passenger Kilometres

- IATA: The International Air Transport Association

Structure of Dissertation

This paper has been divided into five sections. The first chapter is the introductory chapter which describe the background of the company, research aims and objectives and research significance and limitations. The second chapter is the literature review which discusses the early research work in the relevant area.. The third chapter is the Research methodology section which describes research design, data collection process, sampling and other aspects of research design and methodology. Findings and analysis is the fourth chapter of the report in which the primary data has been presented and analysed. Conclusion and recommendations is the fifth and last chapter of the report which summarises the major findings of the report and highlight important suggestions.

Literature Review

This chapter provides a deep insight to the findings, conclusions and opinions of the early researchers in the relevant area.

Aircraft Maintenance

Samaranyake et al. (2002) have attempted to examine the submission of a unitary software structure for the large scale maintenance activities related to the aircraft industry in order to save both time and money during the maintenance of large number of aircrafts. The researchers have the view that since aircraft maintenance is a highly arduous and painstaking job, which takes huge amount of time, money and resources, imperative steps have been taken in this regard in order to save the precious time, energies and cost as well. The researchers have concentrated upon the software systems for the performing of critical path methods in order to devise and implement a comprehensive, quick and speedy strategic scheme for the aircraft maintenance. The authors pay due heed to the planning phenomenon and declare both planning and scheduling as essential elements from articulating a scheme and making it operational to introducing it in the market and suggesting of adequate amendments in the design, logo, shape and maintenance procedure.

The researchers have defined the terms like critical path method (CPM), material requirements planning (MRP), production activity control (PAC) and others in order to clarify their research and explain the saving methodologies as well. “CPM”, according to the authors, “is a project management technique, where closed network projects, composed of activities and events, are scheduled in terms of the start and finish times of each activity and event.” (2002: p 844) Hence, CPM determines the beginning and ending of a project, and consequently contains imperative significance in its scope for consuming least energies and time during the maintenance process. The authors state that large scale planning is essential for the growth and development of an organisation as well as for the maintenance procedure of aircraft machinery, so that the aircrafts could be repaired and overhauled without the wasting of time and money. They view MRP and PAC techniques advantageous for the aircraft maintenance strategy, because both these schemes are adopted and observed by an overwhelming majority of the aircraft maintenance companies all over the globe. The authors also throw light upon the general maintenance problems the aircraft industry undergoes, which requires heavy labour and plenty of time as well. “General commercial aircraft maintenance”, Samaranyake et al. submit, “consists of number of problem area, such as hangar scheduling, heavy maintenance scheduling, maintenance planning at various levels and engine maintenance. Scheduling a number of aircraft for maintenance at various levels is a huge task for the airline industry, because much of this maintenance involves planning, scheduling and control of a large number of components such as materials, activities, resources and suppliers.” (2002: pp 845-46)

The researchers have also cited the aircraft management and maintenance approaches with reference to the studies made by different researchers time and again. They refer to Brosh, who had divided the maintenance process into two categories i.e. mathematical and engineering. The former category focuses on the development of optimal models for the maintenance initiation, while the later is interested in formulating the acceptable set of maintenance tasks. Samaranyake et al. further elaborate their argument by pointing out more aircraft maintenance models including terotechnical model, life-cycle cost approach, EUT model and others, all of which are observed by an overwhelming majority of the maintenance companies in general. It is therefore Indian Airlines and other companies also apply the same methodologies. “Both Air India and Indian Air have their jet and engineering shops in Mumbai and Delhi respectively which are equipped to carry out `C’ checks but constraints on their capacities often lead to the two carriers outsourcing major engine repairs to workshops in Korea, Hong Kong and Germany. While for each A-320 aircraft a `C’ check costs between $300,000 and $500,000, for bigger aircraft of Air India the cost can go up to $1.5 million per aircraft.” (Quoted in researchwikis.com)

Komorowski (2003) has supported the introduction and application of latest machinery and equipments for the maintenance of aircrafts in a refined manner. The author is of the opinion that in order to make the maintenance economical and comprehensive, frequent overhauling of aircraft is a must. If a company makes unnecessary delays in the maintenance procedure, it has to make ransom amount because of the negligence it has made in respect of look after the repairing of an aircraft. It is therefore, regular and comprehensive maintenance of commercial and fighter aircrafts is extremely necessary for the safety of the passengers as well as of the staff members. If the aircrafts are not maintained properly, the life of the passengers will remain at stake, and accidents and untoward situation could take place any time during the flight and travelling. In addition, the repairing procedure will become lengthy, time consuming and expensive. Moreover, sometimes negligence from maintenance may turn the aircraft defective and out of order. Komorowski vehemently supports the comprehending with the structural integrity issues the researchers have discovered for the aircraft maintenance, implementation of which is highly recommended by the theorists and researchers alike. The author recommends tear-down procedure as the best one for discovering the defects of an aircraft. He observes that as autopsy is considered to be the best method of discovering the cause of a person’s death, tear-down procedure is extremely helpful in discovering the causes of technical problems of an aircraft. “The Institute for Aerospace Research (IAR)”, Komorowski observes, “of the National Research Council of Canada has accumulated a collection of over 700 sections of such aircraft, from small 500mm long fuselage lap joints to A320 vertical stabilizer and an entire Boeing 727 donated by First Air, a Canadian airline.” (2003: p 454)

The author has described non-destructive inspection method (NDI) and edge of light (EOL) method as of primary importance during the maintenance procedure of the aircrafts. Both these methods are related to teardown strategies adopted to examine and investigate the technical problems and faults of aircrafts. Both these procedures have been in vogue in almost all aircraft maintenance corporations and firms for the last many decades. The researcher’s study displays his great command over the aircraft management, reparation and maintenance on the one hand, and his vast knowledge about the methods adopted by divergent maintenance companies belonging to pole apart regions, states and countries of the globe at large on the other. Hence, the author successfully explains in details different faults and defects that could occur during the course of time in an aircraft, maintenance of which should be made according to the prescribed mode as well as on the basis of the theories and methodologies articulated by the technical experts. Corrosion and getting rusted is one of the most challenging defects of an aircraft that should be repaired and removed on emergency basis by applying NDI methodology. The author views that removal and clearance of corrosion is not very time consuming, but it requires complete concentration along with the proficient and skilled staff to combat with the corrosion challenge created at the aircraft. NDI is a vast and technically expertise method and is beneficial for different aspects of maintenance.

Komorowski proposes edge of light method too as the second most imperative procedure for the aircraft maintenance. “The second enhanced optical method”, he observes, “is the edge of light (EOL), which is a scanner-based technique that can detect not only pillowing but also surface breaking cracks. Since corrosion may lead to premature cracking, once corrosion is detected, it is important to know if cracks are present as well. EOL will be available commercially in 2003.” (2003: p 455) D sight aircraft inspection system also contains validity according to Komorowski, which is aptly observed by the air forces of various countries. The author also discusses computational and experimental analysis technologies in respect of the aircraft maintenance, both of which have been in vogue for years in almost all countries for the better management of the aircrafts. Life enhancement technologies have also been discussed by the author, which are observed by the maintenance workshops and repairing centres. “Maintenance shops”, he states, “are using a large number of repair schemes, which will continue to be applied along with life enhancement technologies like cold working, shot and laser peening. More recently, the repair toolbox was expanded with techniques like composite patches and retrogression and re-aging.” (2003: p 457) Hence, Komorowski has successfully explained divergent approaches and methods used in aircraft management in his research, which are time reducing, economical and require least number of labourers as well.

Knezevic (1999) has also articulated his approach about aircraft management and maintenance on the basis of his study on this topic. His research, under the title “Chief Mechanic: the New Approach to Aircraft Maintenance by Boeing” concentrates upon the dynamic role played by the chief mechanic while repairing an aircraft. He submits to state that since the performance of an aircraft is directly dependent of the maintenance process, the chief mechanic is the central figure in respect of enhancing the performance and prolonging the life of an aircraft. Knezevic has particularly focused upon the repairing process applied on Boeing 777, where he vehemently suggests that the engineers and designers must keep in view the maintenance cost while designing and creating an aircraft, because the design of the aircraft determines the cost volume spent on its maintenance and overhauling. “When total cost is considered over the life cycle, it is evident that the operating and support costs of the airplane will eventually exceed the initial acquisition cost. In order for Boeing to make the airplane attractive to the airlines, the engineers must include maintenance cost savings in the design. This was done by increasing the reliability and maintainability. Increased reliability means fewer failures to fix. Increased maintainability means shorter maintenance times.” (1999: p 314) Hence, the author has shown direct link of the design of an aircraft with its maintenance cost.

The researcher has also indicated towards the ways to reduce maintenance cost with special reference to Boeing 777 aircraft. He considers schedule reliability as an imperative parameter to measure cost reduction, which could be estimated while examining the take-off time of an aircraft. It has also been suggested by the author that the maintenance of aircraft should be performed according to the schedule determined by the technical staff in this regards. “Reliability requirements”, Knezevic argues, “were passed along to equipment manufacturers by specifying mean time between failures (MTBF) and target mean time between unscheduled removals (MTBUR). The latter was estimated to be between 0.8 and 0.9 of MTBF, but could be verified only by service experience.” (1999: p 315) The author is of the opinion that in order to prepare and present a high quality aircraft, joint effort of the staff members belonging to different departments of the manufacturing organisation is a must. Joint venture to create the logo and design of the aircraft, and produce and present it subsequently not only gives astounding performance, but also helps in reducing the manufacturing and maintenance cost as well. The collect efforts are also helpful in fulfilling the fast growing demands of the customers and suppliers alike in this era of perfect competition, where the price hike is always at the upward trend while the purchasing power of the people is at downward trend due to economic downturn and inflation all over the globe.

Knezevic looks for the every time availability of all the maintenance equipments so that any untoward situation could immediately be dealt with on urgent basis. It is the professional and moral obligation of the designers to design easy, flexible and simple equipments, which could easily be applied at the hour of need. Complicated and heavy equipments may turn out useless and rusted. “The majority of users” according to Knezevic, “state that the equipment availability is equally important to them as its safety, because they cannot tolerate having equipment out of operation. There are several ways that designers can control that. One is to build items/systems that are extremely reliable, and consequently, costly. The second is to provide a system that, when it fails, is easy to restore. Thus, if everything is made highly reliable and everything is easy to repair, the producer has got a very efficient system, which no one can afford to buy.” (1999: p 317) Consequently, Knezevic lays stress upon simplicity and perfection of the repairing equipments in order to make repairing process easy and economical.

Petkidis (2009) has articulated his research work under the topic “Airline Risk Management” in which the researcher has attempted to discover how the three principal European airlines including British Airways, Lufthansa, and Air France-KLM managed to deal with their production and financial risks within such a precarious situation when the oil prices are in constant increase. The focus of his research was concentrated upon identifying of the chief risk factors the airlines experienced during the last five years of operations from 2003 to 2007, along with their individual existing market values, as well as the affects of the contemporary fuel crisis on the corporate activities of the airlines. “Although”, Petkidis states, “it is aptly stated that entrepreneurs devise strategies and take great risks on the basis of these strategies, particularly in the airline industry, yet it is fact beyond doubt that generally they find more confidence in taking risk with governmental support policies.” (2009: p 4) On the basis of the quantitative method of research the researcher adopted while collecting the informational data for his study, the researcher collected the required data from balance sheets, income statements, cash flows, country interest rates and US treasury rates for five years, 2003 to 2007, which was tabulated and computed for total cost, average market value, return on assets and return on equity, existing ratio, debt to total assets, risk premium, firm value, and multiple regressions. On the basis of his study, the researcher concluded that there exists a noteworthy company-profile for the British Airways, Lufthansa, and Air France-KLM for the last five years in terms of: a)Total Revenue; b) Total Assets; c) Net Income; d) Total Debt; e) Total Liabilities; f) Total Equity; and g) Market Value; the companies have short-term debt-paying ability, overall profitability of assets used, profitability of owner’s investment, and percentage of total assets provided by creditors; there exists an imperative firm value for British Airways, Lufthansa, and Air France-KLM for the last five years. The researcher also concluded that the expected risk premium did not prove as a considerable risk factor for the three airline companies for the last five years; and the Middle distillates, jet and heating Kerosene and gas and diesel oils, including marine bunkers prices, did not drastically affect the market value of British Airways, Lufthansa, and Air France-KLM during the last five years. Hence, the in-depth analysis made by the researcher all the three airlines under study sustained their positions even under perturb economic situation.

Knotts (1999) has also focused his research on aircraft maintenance and repairing. His study under the title “Civil Aircraft Maintenance and Support: Fault Diagnosis from a Business Perspective” discusses the ways for saving of time and labour during the maintenance activities. Knotts has also determined various methods to mitigate the ground expenditures spent on the overhauling procedures of aircrafts. He views despatch reliability and direct maintenance costs, as two important yardsticks for measuring the cost implications of aircraft maintenance. The prediction of fault diagnosis activities in quantitative terms of time is vehemently supported by the author. The author also suggests the best possible methodologies to save time in ground maintenance activities for the best interests of the entire airline industry at large, according to which despatch reliability is the primary one that is of imperative significance in respect of maintenance procedure. “Despatch reliability (DR)”, according to the author, is the percentage of revenue departures which do not incur a delay or cancellation as a result of technical problems (ATA, IATA and ICCAIA, 1992) Technical delays occur when the malfunctioning of equipment and related checking and required corrective action causes the aircraft’s departure to be delayed by more that a specified time after the scheduled departure time.” (1999: p 336) Hence, Despatch reliability does not let the technical faults occur and create hurdles for the aircrafts provided the flights depart and arrive according to the schedules decided and determined by the engineers, maintenance mechanics and other technical staff. The author also views direct maintenance costs (DMCs) as an important phenomenon in respect of the aircraft maintenance. “The labour and material costs directly expended in performing maintenance of an aircraft or related equipment.” (Knotts, 1999: p 336)

The researches reveal the very fact that continuous maintenance problems of aircrafts may turn out very expensive, time consuming and problematic, as these directly affect the flights schedule and subsequent financial losses to the airline companies. Time is most important factor of success particularly in this fast age, where the clients do not bother to wait for some specific brand, company or organisation and look for saving of time at any cost. “When a grounded plane can cost tens of thousands of dollars a day in lost revenue that cannot be regained, the concern over the impact of maintenance, repair and overhaul (MRO) and maintenance and engineering (M&E) expense on the corporate bottom line becomes obvious. And the impact is multiplied by the number of aircraft needing maintenance at any given time out of the thousands of aircraft in service today.” (Retrieved from sap.com) Knotts also suggests further methods for the reduction of maintenance costs in respect of reparation process, which include servicing turnaround time, system and equipment reliability and maintenance down time. Servicing turnaround time in a perfect and in an apposite way reduces the probabilities of expensive reparation of the aircraft. Turnaround time is the time when the passengers and luggage is downloaded and uploaded from the aircraft, and cleanliness is performed along with the refilling of fuel and checking out the overall condition of the aircraft. It is the best time, according to the author, to apply the operational and maintenance theories to minimise the expenditures being spent on overhauling of the aircraft. “As daunting as this may seem, the challenge is amplified by the persistent, industry-wide pressure to introduce new efficiencies to further reduce maintenance and engineering costs while simultaneously increasing and maximizing operational availability of the fleet. The pressure is justified, because any aircraft delayed in maintenance is missing revenue-generating opportunities and increasing overall maintenance costs. Time is money, and maintenance organizations that can harness their experience and provide mission-critical maintenance support services in the most robust manner will gain competitive advantages and reduce overall turnaround times.” (Retrieved from sap.com) Knotts argues that all the systems introduced by the competent technicians and engineers describing saving methodologies are important and contain worth in them, though some of these systems are more beneficial and supportive in respect of quickly accomplishing the reparation task with the help of only few staff members. “Every system and associated component has a function to perform. The primary objective of maintenance is to keep the system serviceable, and thus available to perform that function. When the system fails the maintenance technician has to diagnose the fault and rectify the failure as quickly as possible to return it to a serviceable condition. While test procedures and maintenance manuals contain recommended steps for detecting and rectifying defects, their use alone does not guarantee success in timely diagnosis and repair.” (Knotts, 1999: p 337) Knotts states that the ground staff should not let the crew make delays in flights and uploading procedure, so that time could be spent in the overhauling procedure for the long life of the aircraft.

Financial, Auditing and Pricing

Auditing in all the business areas, including field audit, customer audit, staff audit and operational audit, was conducted and risk volume was estimated with old and changing business environment, which helped the department determine and introduce revised business strategy on the foundations of contractual, accounting and economic exposures contained by the Continental Airlines in order to measure the three levels of risks the company had been undergoing. The department developed a process to assess the risk of the financial and operational units by evaluating the financial, inherent and reputational risks of the company. This risk assessment includes analyzing the balance sheet and income statement for large dollar amounts; obtaining a detail hierarchy of the accounts and analyzing large budget variances and related explanations; identifying if the business unit is performed solely in-house or serviced by a third party vendor; discerning the likelihood of errors and strengths of controls associated with the unit; assessing prior audit results for the unit; ascertaining if a new area or major changes to an area have incurred; and identifying areas impacting corporate image and regulatory compliance. (Goepfert, 2006) In addition, the finance department remained in continuous contact with the management to understand their concerns and identifies current issues or ‘hot button’ items to identify the timing for which the audit should be performed (sooner versus later). Hence, the airline successfully combat with the growing risks on the way to its growth and sustained its position as the sixth largest airline of the entire world.

Richard Cobbs & Alex Wolf (2004) has conducted his research on the topic “Jet Fuel Hedging Strategies” with reference to airline industry and presented the information regarding the necessity of hedging in order to counter the losses and manage the rising risks as the consequence alterations in social, economic, political, corporate and technological scenario. The authors have pointed out various strategies including hedging over-the-counter derivatives, future contracts, and not-hedging while highlighting the merit of all these strategies. Cobbs & Wolf view collar structures and swaps as two forms of over-the-counter strategies implied by the airline industries. Over-the-counter (OTC) strategies are traded directly between the airlines and investment banks, and as have counterparty risk that must be considered. Therefore, most airlines prefer to trade with three or four different banks to diversify and also to get the best pricing possible. (Cobbs & Wolf, 2004: p 29) A vibrant, powerful and energetic hedging, airlines and other corporation require variation in the products over the oil price cycle to mitigate losses and combat risks. When oil is in the low price cycle, receive-fixed swamps are used because the likelihood of further price declines is not considered as probable as price increases, and the swamp contract allows the airline to lock in the relatively low price. In the mid-range of the cycle, collars are used to lock in a specified range of prices, giving up potential savings from price depreciation while hedging against further increases. (Cobbs & Wolf, 2004: p 57)

Mirghani (1996) has articulated his research task with the title “Aircraft Maintenance Budgetary and Costing Systems at the Saudi Arabian Airlines: An Integrated Business Approach”, where the author has defined various economic aspects related to the maintenance of aircrafts with particular reference to the Saudi Arabian Airline. He is of the opinion that the airline under study strictly observes all the instructions issued by the maintenance review board (MRB) to escape any extra amount and budgeting deficit created because of any extra labour to be allocated and reparation to be made to keep the aircrafts up to date. “The Saudi Arabian Airlines (SAUDIA)”, Mirghani observes, “abides by all of the MRB’s requirements as well as by the Federal Aviation Administration (FAA) rules and regulations which have been adopted in their entirety by the Presidency of Civil Aviation (PCA). These rules and regulations cover aircraft manufacturing and spare parts; operating into the USA (FAR 129); how to operate an aircraft (certification to fly, FAR 121); and certification of aircrafts and related parts (FAR 121, Part 25). (1996: p 33) The management and authorities of the airline under study are of the view that in order to compete with the world class airlines in this age of perfect competition, the on-time technical reliability of the aircrafts is very much necessary. The airline administration draws out an in-depth strategic scheme in respect of budgeting, where it pays due heed to the best possible ways for aircraft maintenance, but does not allow extra expenditures created due to the negligence of the reparation and overhauling staff.

Researches declare risk management as the most imperative part of the strategic analyses for the survival and growth of all organizations and corporate firms. The process used to systematically manage risk exposures is known as risk management. (Trieschmann et al. 2007) Goepfert (2006) has conducted his research on airline risk management with special reference to Continental Airlines, and proves the very reality that airline industry has to tackle with new challenges in the aftermath of latest changes in the global corporate environment for its continued existence. Goepfert refers to the financial and operational crises appeared in the wake of the Gulf War of 1990 and the 9/11 terrorists’ attacks affected the industry subsequently. As a result, the corporate audit department of the Continental Airlines conducted a comprehensive audit within the financial and operational divisions of the airline company in order to mitigate the expected risk in a proper way. In the early 1990s the department used a cyclical approach to performing reviews with an emphasis on financial and accounting functions. (Goepfert, 2006) The rapid increase of oil prices and fluctuations in the US dollar put financial estimates of different airlines in grave jeopardy. Dollar value expended or generated by the area primarily drove the process and management requests were considered. However, the financial control department realized that other risk areas remained outside the normal audit focus, and that the timing of audits didn’t always correlate with the relative risk environment currently existing in the company. (Goepfert, 2006)

Human Resource Management

Human resource management is one of the most crucial aspects of the airlines maintenance service providing company. The nature of the job is highly technical and requires technical qualifications and skills. Varieties of technical skills are needed from the workforce in order to fulfil the requirement of maintenance of an aircraft such as maintenance shops for aviation maintenance technicians. Aircraft companies obtain these services in two forms in-house and outsourced. Sometimes all the maintenance services are outsourced like local contract maintenance facility or number of facilities (Sheehan, 2003). Krishnan (2008) aircraft maintenance services are extended to the maintenance services of military aircrafts.

Companies in the aircraft maintenance services provide services to their client. These services are specialised services. The concepts of services marketing are applicable in the case of aircraft maintenance services. Reverse to the Say’s law, in the case of aircraft maintenance services majority of the revenue comes from the majority of clients. This is highly specialised service. The number of aircraft companies is limited.

Marketing and Communication

Cheung, Ip and Lu (2005) have also performed their study work under the topic “Methodology and Theory Expert System for Aircraft Maintenance Services Industry”, in which they have elaborated both the expert theory and methodology observed by the aircraft maintenance industry in Asia and Europe. The researchers have concentrated their study on the Chinese airline industry, though their study can also be viewed as the comparative research throwing light upon the overall maintenance phenomenon related to the aircrafts. The basic motive behind their research work is to calculate and assess the allocation of proper labour for obtaining best results in overhauling procedure. The researchers consider mathematical programming as the superior one, which is estimated to be the common modelling approach witnessed and exercised by the proficient and brilliant chief mechanics. The selection of skilled and dexterous staff is really hard nut to crack fort the aircraft management, because the technical staff is generally selected on the personal liking and disliking of the decision making authorities. “Current engineer selection process is mainly relied on the decision-maker’s own experience without systematic approach, which is apt to be biased due to limited personal experience, knowledge and perception.” (Angus et al., 2002: quoted in Cheung et al., 2005: p 349) The researchers propose the allocation of right person at the right place so that diligent and efficient staff could supervise the entire maintenance process under the dynamic leadership of competent managers and chief mechanic as well in order to avoid any untoward situation in the aircraft maintenance process.

According to Porter (1990) competitive advantage helps company to maintaining its strategic condition. There are various factors like lower-order advantages, competitive labour and material cost. Companies adopt differentiation strategies and marketing mix. Cost based strategies rules the airlines services industry where the number of service providers has increased. However in the case of aircraft Service Company, the number of service providers is limited. Sustainability of cost advantage is low as compared to the differentiation. Cost leadership when combined with differentiation strategy can provide sustainable competitive advantage. According to Wu, Liu and Liu (2004)

“Commercial aircraft maintenance activities form an essential part of airworthiness. Aircraft maintenance is actions that can restore an item to a serviceable condition, and consist of servicing, repair, modification, overhaul, inspection and determination of condition.”

Conceptual Framework

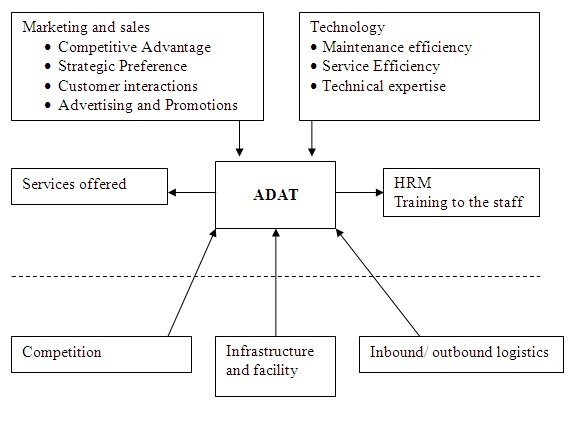

The conceptual framework for this study has been presented in the figure 3. The figure shows the factors of marketing & sales and factors of technology that affect the services offered to the client and the human resource aspects of the company. The competition in the business environment, infrastructure and facilities and inbound/ outbound logistics are the factors affecting the services offered to the clients and human resource aspects.

Figure 3 Conceptual Framework

Research Methodology

Overview of Research Questions

The first research question covers the strategic business environment for Abu Dhabi Aircraft Technologies (ADAT). It is evident from the literature review that there have been limited studies that were aimed to understanding the business environment for the aircraft maintenance service providers. The second question aims at studying the competitive business scenario for ADAT. The airlines and aircraft manufacturing companies also provide services for the aircraft maintenance which creates competition for the company. Therefore, it is important to study these aspects and understand the factors significant for the sustainability and growth. The last research question is an effort to explore the factors for sustainability and growth.

Overview of Literature Review

Knezevic (1999) concentrated on the role of chief mechanic repairing the aircraft. This study established relationship between the design of an aircraft and the cost of maintenance. Direct maintenance costs are labour and material costs which are identified as the most important costs by Knotts (1999). There were some studies that focused on the maintenance activities and its relation with the time and money saving (Samaranyake et al., 2002). This study indicated that use of software systems for performing critical path methods helped in reducing the time, cost and energies. There were several tools like CPM, MRP and PAC which can be employed in improving the overall effectiveness of the maintenance activities. In other study Komorowski (2003) supported the introduction and application of latest machineries. Cheung, Ip and Lu (2005) studied the relationship between the access and allocation of labour and results of overhauling process in Chinese airlines industry and concluded that the selection and recruitment of skilled staff is one of the toughest tasks for the airline maintenance companies. Goepfert (2006) proves the very reality that airline industry has to tackle with new challenges in the aftermath of latest changes in the global corporate environment for its continued existence. Petkidis (2009) concluded in his studies that the expected risk premium did not prove as a considerable risk factor for the three airline companies over the last five years. There are various discussions over the maintenance and related activities. These studies in the past were either conducted in an airlines company or for the overall industry itself. However there are negligible studies which covered the strategic business environment of any aircraft maintenance service providing company. These companies play significant role by providing maintenance facilities which an airline company cannot conduct on its own due to the lack of infrastructure and resources. This makes the outsourcing of maintenance services more demanding for the target customers. The aircraft manufacturing companies like Boeing, Airbus and others provide aircraft maintenance services to their clients which are available for their manufactured aircrafts. However these facilities are limited to certain locations. The presence of private aircraft maintenance service providers thus become important for the airline maintenance services. This is a unique service offered to highly valuable clients with low volume.

Research Design

The research design of this study is based on the case study approach. The methods of data collection consist of survey method and desk research.

Research Methods

Both the qualitative and quantitative research methodologies have been adopted to investigate the research questions.

Secondary Research

Secondary information has been collected through the various reliable secondary sources such as corporate websites of the major aircraft such as official website of ADAT, journals and books, industry reports, IATA websites and other sources of information like news portals. The secondary data has provided useful information regarding the external environment of the business.

Primary Research

Primary data has been collected with the help of structured questionnaire. The data has been collected by conducting a survey at ADAT. The employees of the company from all levels of hierarchy were encouraged to participate in the survey. The total sample size was 137 however, only 96 questionnaires were found to be completely filled, which means that the actual sample size of the survey is 96 participants. The questionnaires were distributed both by hand and via mail and email. Some questionnaires were also got filled by contacting the employees over phone. The collected data has been very useful in the internal analysis of the company. All the respondents were informed regarding the research process. The voluntary participation (Creswell, 2007) of the prospective respondents was taken before getting the questionnaires filled

Primary research yielded in statistical data. Researcher conducted descriptive analysis of the data.

The quantitative data has been collected through the survey. The questionnaire consisted of closed-ended questions with predefined responses. Choices of each question were provided in the questionnaire and respondents were requested to choose the most appropriate answer. Some questions were ranked-based questions where respondents were requested to rank their responses based on their personal opinions.

Data Collection Tool

Sampling

Through the sampling process the prospective respondents who were working in ADAT and maintenance section were approached for their participation in the survey. The total number of employees working in the organisation ADAT was 2500. The random sampling was used to select the respondents of the survey.

According to Saunders, Lewis & Thornhill, (2007) strategic sampling offers economic advantage to the researchers. This saves valuable time and financial resources and helps in providing critical information for the research (Saunders, Lewis & Thornhill, 2007). This survey was based on convenience based sampling where each respondent was approached randomly and based on convenience of researcher and respondents, the survey data has been collected.

At the confidence level of 95% and confidence interval of 10, the sample size the sample size of the population is calculated to be 93. This calculation is based on assumption that all the maintenance staff has similar knowledge.

Sampling

- Definition of Population

The people working in the engineering department of ADAT constitute the population of this research study.

- Specify Sampling Frame

These are the people working in the maintenance tasks for the aircrafts in the ADAT.

- Specify Sampling Unit

Sampling unit consists of the professionals working in the maintenance areas for the aircraft.

- Specify Sampling Method

Researcher has used a mix of convenience and the non-probability sampling methods in this research. This is due to the fact that all the prospective employees are from the maintenance service providing company. It allowed the collection of data simpler, easier and time efficient.

- Determination of Sample Size

The questionnaire has been designed to collect ordinal and non-parametric data. Some studies suggest that sample size for ordinal data should be 5% more than the nominal data. Some other important factors like feedback of academic and industry experts, time and cost of data collection have been also considered.

Assuming all the employees in the organisation have similar exposure to the internal environment of the organisation, the respondents have been approached. According to Ott (1993) thirty is statistically valid sample size for the use of academic purpose. However researcher has tried to keep the sample size higher than this number in order to receive better response.

Data Collection Procedure

Researcher collected data personally from each respondent in their organisational settings. All the prospective respondents were contacted in person, greeted and asked if they could spare some minutes. Once the individual agreed, he was explained about the research objectives, purpose, potential risks and benefits and clarified that the confidentiality and anonymity of the responses would be maintained. Once prospective respondent agreed for the voluntary participation, researcher provided him the copy of questionnaire. Some respondents requested to send the questionnaire through e-mail. In such cases, questionnaire has been forwarded on their email addresses. This process of data collection was stopped once sufficient amount of data was generated. Keeping the risk of incomplete data, researcher got 137 questionnaire filled. The incomplete questionnaires were excluded from the study. It has been analysed that response rate for the data collected personally is higher as compared to the data collected online, via mail or telephonic.

Number of respondents filled the questionnaire=137

Complete questionnaires=96

Response rate=70%

Validity

Researcher tried his level best to collect the data from the most reliable sources and serious respondents. The findings have been compared with the other studies of similar nature (Saunders, Lewis & Thornhill 2007).

Ethical Considerations

Researcher informed the study scope, purpose, objectives and use of the data collected to all the respondents and ensured them that their personal information and participation will be confidential and anonymity would be maintained. They are offered copy of the final project, if they are interested. No compensation in cash or any kind has been given to any of the respondents. These have been voluntary participation. No identifiers are used in the data presentation. However, the socially acceptable answers and the personal motives and interest of the participants may limit the scope of this research study.

Findings and Analysis

Findings of Secondary Research

For the secondary analysis, maintenance service pattern of major airlines of Middle East are studied. Following is the finding of this study:

Emirates Airlines

- Emirates Airlines has a Line Maintenance in Dubai. This is a network of outstation teams.

- This division provides a 24-hour service. Emirates Airline and other airlines through Dubai International Airport receive the services provided by this division with the highest levels of technical support.

- This team consists of technically-skilled engineers and technicians. These team members are licensed from concerned regulatory authorities.

- ‘Emiratesprovides services to the other airlines companies.

- Emirates’ maintenance facility is also known as Emirates Engineering and it is one of the world’s largest facilities.

- Emirates facility carries extensive maintenance activities like extensive interior reconfiguration and retrofitting of its wide-bodied fleet.

- Emirates has a fully equipped paint facility. According to the Emirates Annual Report (2009) the paint facility is one of the top three facilities in the world.

“During the year, the division refreshed 16 out of 29 A330 cabins and all eight A340-300 were upgraded with new interiors.” (Emirates Annual Report, 2009)

- Emirates carries out heavy maintenance for the Airbus and Boeing fleets. As stated in Emirates Annual Report (2009), “By the end of the year, 40 of the A330s, A340s and Boeing 777s had been fitted with GSM modifications to enable passengers to use their own mobile phones. The refurbishing and retrofitting of the Boeing 777s requires each aircraft to be in maintenance for up to 45 days and includes the installation of new First, Business and Economy Class seats, in-flight entertainment system, toilets and galleys.”

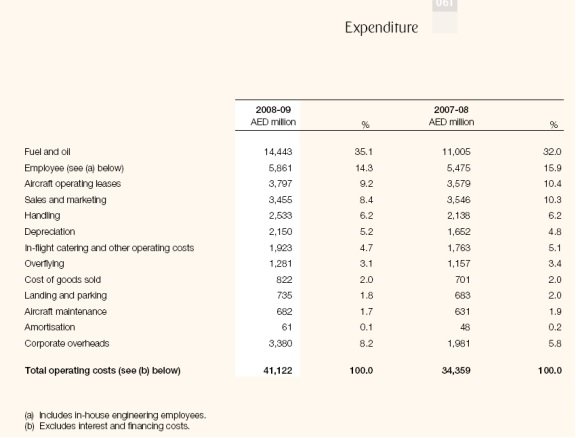

- Emirates’ maintenance facilities have experienced growth of 20% from 2008 to 2009 and significant cost reduction.

- The overall expenditure on the Aircraft Maintenance was 1.9% in the financial year 2007-08 alone. The reduction was 0.2% in that financial year and in the year it reached to 1.7%.

- The cost implication was saving of AED 51 million in the financial year 2008-09. The organisation experienced increased in the total operating cost.

Figure 4 Expenditure of the Emirates

Maintenance of Saudi Arabia Airlines

- The maintenance base of Saudi Arabian Airlines is based at Jeddah.

“Saudi Arabian Airlines can carry out 90 percent of its own engine maintenance work and will soon be able to offer overhaul services to foreign airlines, according to a senior airline official” (Arab News, 2010)

- The maintenance facility of the Saudi Arabian Airlines perform maintenance at various levels.

“Complete engine maintenance for the B747 classic fleet and the MD90 fleet. We are now developing the capability for the maintenance of Airbus 320 fleet engines and APUs (auxiliary power units)” (Saudi News, 2010)

- Saudi Arabian Airlines are also developing a new power plant maintenance facility which will spread over 50,000 square meters power plant with APU maintenance services to other operators. (Saudi News, 2010)

Findings of ADAT Secondary Data

In the Table 1, it is clear that the number of resigned staff has drastically increased from the year 2008 to 2009 after the takeover GAMCO in 2008. Mubadalah took over GAMCO from date of 01-JAN-2008. This takeover was followed by the organisational restructuring. Restructuring was directly linked with the payscale of the employees. Employees received much below than expected increment on their salaries. The cost of living during this period also increased (AbuDhabi CPI report) which enhanced the burdens on the employees. The employees did not receive better increment after three-years-long waiting period. This resulted in high dissatisfaction and unrest. As a result, technically qualified staff started looking for better opportunities. As soon as any employee got competitive offer, he left the job. In this way many experienced, skilled and star employees left the company. Moreover, recruitment and replacement costs of these employees were high.

Table 1 Employee Turnover from 2008-2010

| 2008 | 2009 | 2010 | |

| Total Resigned Staff | 208 | 435 | 364 |

| Senior Staff ( Managers, Assistant Manager, Snr Supervisor) | 17 | 51 | 56 |

| Aircraft Engineer | 29 | 200 | 147 |

ERP

ADAT was using Meline system before using Oracle ERP system. The old system used was not user-friendly. There were problems of accrual data inventories and complex tasks. With growing needs of business, the problem of consistency and scalability of the system also raised. ERP implementation resulted in significant improvement in overall efficiency.

HR and Finance

The ERP system helped in improving the operational efficiency of these two departments in a major way. It helped in reducing time required for doing the same task and maintaining proper inventory system. The number of people required for running and executing task in the Merline system was much more than required in new ERP system. The documents were filled manually and sending them to and from the department to finance or HR through office boy was a time-consuming process. In short, the probability of errors was high.

There was no inventory system which could count the total request in the month or see the work flow and pending. There was no access to employee file such as qualification and skills and employee certificates in the previous system. After implementing the ERP system organisation was able to streamline everything from automating the work flows to defining the company report hierarchy in the system. There are various features of the new system like notice, flow, prioritization of jobs and others.

The HR and Finance systems have a Discoverer report system that allows access to system inventory. They help to retrieve all employees’ data and most importantly the wastage time reduced to 90%.

MRO:

One more system, MRO was used for the very low inventory. It was another time-consuming process and required many people to work on the system.

The implementation of ERP took more resources and lack of resources increased the complexities.

Moreover, the cost of training was high for the ERP implementation.

Now the big challenge for the company was the training of the people because the new system was not working to its potential. It is because of the two reasons; first, the system is new for the existing employees; second, most the technical employees have very limited knowledge of IT and new system. The company has spent more than $10m on the ERP system and training.

Average Turnover

The turnover ratio decreased from 18% to 7% in 2009. At the same time, this figure increased to 14% in the year 2010.

Table 2 Turnover Ratio 2008-2010

| 2008 | 2009 | 2010 | ||||

| JAN | DEC | JAN | DEC | JAN | DEC | |

| Headcount | 2867 | 3214 | 3214 | 2999 | 3010 | 3062 |

| Average Headcount | 3040.5 | 3106.5 | 3036 | |||

| Employee Joining | 555 | 220 | 416 | |||

| Employee Resigned | 208 | 435 | 364 | |||

Reason of Turnover

There are various reasons of high turnover in 2008. The main reason has been low wages and apart from the low wages; low morale, failure of implementation of effective performance review and system, lack of employee development and career opportunities and failure in employee retention. Employees perceive that expected returns of the efforts are low which create job dissatisfaction and employee turnover.

Replacement Cost

The replacement cost of the employee reduced in 2009 and then increased again in 2010.

Table 3 Total Employee Replacement cost from 2008 -2010

| 2008 | 2009 | 2010 | |

| Total Joining Employee | 555 | 220 | 416 |

| Snr Employee | 38 | 44 | 69 |

| Aircraft Engineer | 150 | 55 | 82 |

The cost of recruitment depends on various factors like recruitment cost, senior employee cost, advertising and headhunting process. A tentative cost as per responsibilities is given below:

a. Joiner Employee cost = from 2000$ to 3000$ (include Visa fees, Joining air ticket, joining accommodation for two weeks)

b. Senior Employee cost = from 7000$ to 10000$ (include Visa fees, Joining air ticket, joining accommodation for two weeks)

c. Advertising = from 3000$ to 6000$

d. Headhunting = from 10000$ to 20000$

Cost of Training

Training cost for engineers ranges from $3000 to $5000 per head.

Findings of Primary Research

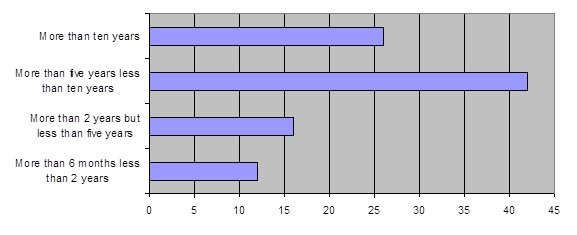

Total 42 respondents (approximately 44% of respondents) have more than five years and less than ten years of experience. 27% of respondents have more than ten years of experience. Total 12.5% of respondents have less than two years and more than 6 months of experience.

Figure 5 Experience

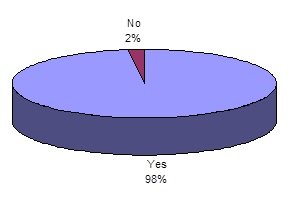

98% of the respondents are associated with particular zone of the aircraft maintenance.

Figure 6 Associated with particular zone

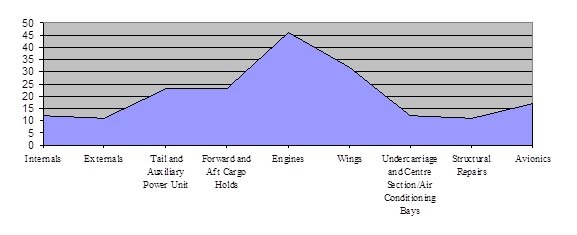

Majority of the respondents working in the engines zone is highest with more than 48% of the respondents working in this zone. This is followed by wings zone where more than 33% respondents working. 24% each respondent are working in tails and auxiliary power units and forward and Aft Cargo holds. Less percent of respondents (nearly 11%) respondents are working in external zones. 12.5% respondents each are working in internals and undercarriage and center section/air conditioning bays.

Figure 7 Respondents’ Association Zones

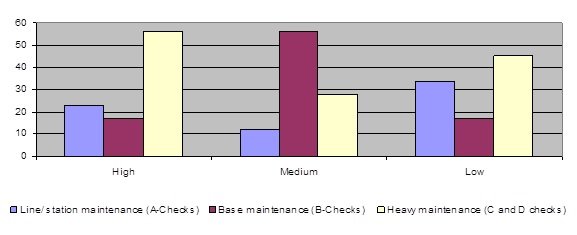

The highest respondents have medium involvement in base maintenance (B-Checks), followed by high involvements in heavy maintenance (C and D checks). The line station maintenance has the lowest involvement.

Figure 8 Involvement of Respondents in Maintenance Activities

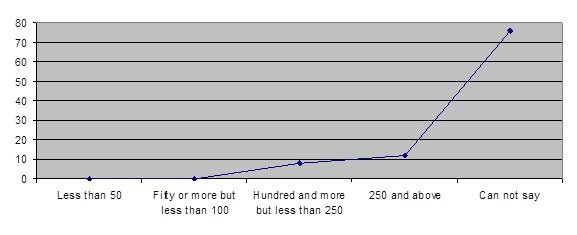

Nearly 79% respondents cannot say about the number of people working in their aircraft zone, this is followed by 12.5% respondents agreeing that 250 and above respondents are working in their aircraft zone and nearly 8.3% respondents have number of people working in their aircraft zone is more than hundred but less than 250.

Figure 9 Number of People Working in Aircraft Zone

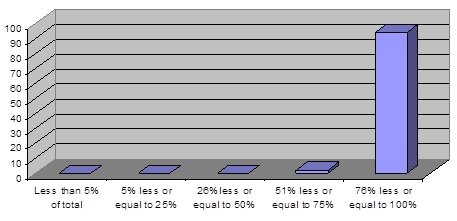

When respondents were asked about percent of technical people working in their aircraft zone, 98% respondents feel that76% to100% people working in their aircraft zone have technical qualifications. This is followed by 2% respondents who feel that 51% to 75% people working in their aircraft zone are technical.

Figure 10 Percent of Technical People in Aircraft Zone

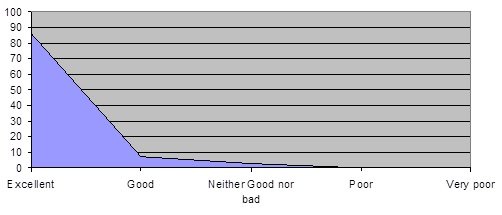

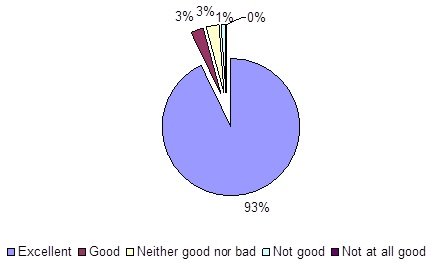

89.6% respondents perceive the services of their organisation are excellent, followed by 7.3% respondents perceiving it to be good. The remaining respondents perceive it to be neither good nor bad.

Figure 11 Ranking of Organization for Maintenance Services

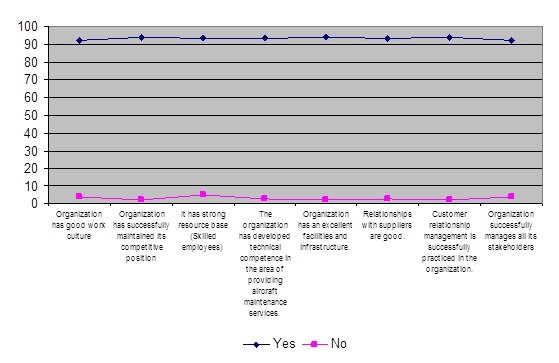

Employees have positive perception regarding all the aspects of the organization. Organisation has good work culture (95.8%). Organisation has successfully maintained its competitive position (97.9%). It has strong resource base (Skilled employees) (96.9%). The organisation has developed technical competence in the area of providing aircraft maintenance services (96.9%).Organisation has an excellent facilities and infrastructure (97.9%). Relationships with suppliers are good (96.8%). Customer relationship management is successfully practiced in the organisation (97.9%). Organisation successfully manages all its stakeholders (95.8).

Figure 12 Perception of Employees

Majority of respondents (93%) perceive that organisation is excellent in maintenance services, this is followed by 3% who consider it to be good and neither good or bad and 1% respondents perceive it not good.

Figure 13 Performance of the Organization

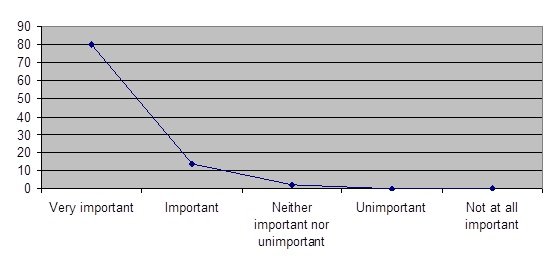

83.3% respondents feel that training for the personnel doing maintenance activities is very important. It is followed by 14.5% respondents who find it important and 2% who feel it is neither important nor unimportant.

Figure 14 Role of Training

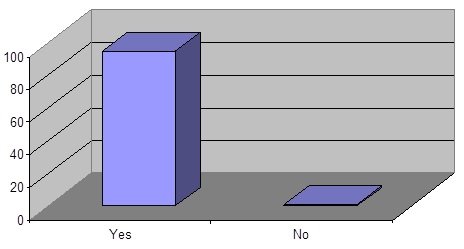

99% respondents feel that overall efficiency of the organisation can be improved by adopting different strategies to provide services to its clients whereas remaining one percent do not agree to the same.

Figure 15 Overall efficiency of the organization can be Improved

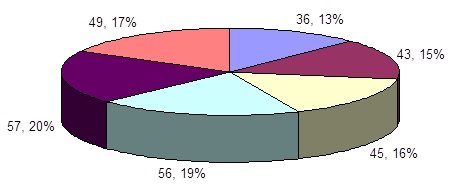

When respondents were asked regarding their opinions on the measures useful in the present scenario to improve the efficiency, 37.5% respondents feel that more technical training needs to be provided. 44.8% respondents agreed for outsourcing. Adopting strategic tool like TQM is favoured by 47% of the respondents. Reduction of wastages is perceived to be the best strategy by 58.3% of the respondents. 59.4% feel that proper planning of resources and 51% respondents feel competitive salary to be the best strategic choice.

Figure 16 To improve efficiency in the Present scenario

Conclusion and Recommendations

This study has an aim of studying the business environment of an aircraft maintenance company. This study also aims at identifying the factors leading to strategic change to the company. In order to achieve the aim, the research objectives were developed to analyse the competitive business environment of Abu Dhabi Aircraft Technologies (ADAT), to critically evaluate the current business strategy of Abu Dhabi Aircraft Technologies (ADAT), to identify a range of strategic options open to Abu Dhabi Aircraft Technologies (ADAT), to evaluate strategic options and to identify better options for Abu Dhabi Aircraft Technologies (ADAT).

The research questions seek to investigate the elements of strategic business environment for Abu Dhabi Aircraft Technologies (ADAT) and type of competition exists for company like Abu Dhabi Aircraft Technologies (ADAT) in the current business environment. Moreover, it aims to investigate how Abu Dhabi Aircraft Technologies (ADAT) can sustain and grow in the current business environment.

In the Middle East airlines companies, the competition of the aircraft companies is growing with the growth in the airlines market. Some of the operating airlines companies like Emirates and Saudi Airlines have their own maintenance base where they provide aircraft maintenance services to other airlines too. Companies like Boeing and Airbus also provide aircraft maintenance services for their aircrafts at certain terms and conditions. This makes the airlines maintenance competitive. However in the present scenario the number of aircraft maintenance service providing companies is limited. This is due to extensive capital requirements, resource requirements and the high knowledge and qualification required by the professionals working in the maintenance. Emirates has one of the best maintenance base at Dubai. Saudi Arabian Airlines is based at Jeddah.

The primary research findings reveal that the organisation has strong base of technically-qualified and skilled workforce. The workforce in general has positive attitude towards the organisation, its facilties and abilities to provide maintenance services. Most of the respondents worked in different maintenance zones.

There are sequences of activities which are performed in aircraft maintenance. These activities are performed in specific orders. The time taken for each individual activity is combined to get the overall estimate of the time. There are some activities which are performed simultaneously. Skills required to work at different zones varies. The concerned persons determine job priorities, identify availability of the technical experts and allocate work to the concerned person.

It is clear from the literature review section that the aircraft maintenance is one of the most important aspects for airlines companies and appears as an important strategic tool for them. Airlines maintenance activities are required for various aspects of operations of an aircraft and vary from line checks to heavy maintenance services. In this way, the airline incurs two major costs; one rising from the costs of maintenance and other rising because of the non-operational aircraft during the maintenance process.

From 2008 to 2009 the employee turnover increased as evident from the increased employee resignations. The recruitment and selection process is time-consuming and costly as compared to the cost incurred to retain employees. Particularly in the area of aircraft maintenance, finding a skilled and experienced employee is a challenging task for the recruiters.

In UAE or in the same region experience employees with this competitive salary range and ADAT is the lowest, therefore the recruitment team needs to travel out to the Africa or north USA countries to bring engineers and technician that is an additional cost. The additional costs include accommodation, travelling allowances and other costs. For the newly recruited engineers the companies need to get the license approval from the UAE aircraft maintenance.

The UAE aircraft Maintenance Company and Etihad airways aircrafts fleet are the major customer for ADAT. Therefore ADAT started losing the experienced staff and lose a big budget on the recruitment and selection processes. This also affected the business and delivery of services. Lack of manpower resulted in poor output or delayed services. In the Airframe services and workshops where the number of technical staff is high, the turnover reported is the highest and company has been spending in recruitment and training processes. The company has already started investing money to build a complete training section with full facility and class rooms. Nearly one million dollar is being spent on recruitment assessment system to choose a best employee through conducting a psychology test. The test will help management to select the best employee in a best position as per test results.

In heavy maintenance the aircraft is dissembled completely by the technical experts. Therefore, there are dual cost implications of maintenance and cost of non-performance. Heavy maintenance makes the aircraft reach to the zero-flying hour level. This makes it almost new aircraft. The clearance of aircraft for being operational requires collaboration with the production, engineering, maintenance, services and others. The cost implications of direct maintenance are linked with man-hours, labour rate and material costs. There are other factors that influence direct maintenance of aircraft like environmental, design, competition and faulty diagnosis factors, quality, leadership, integration of processes and continuous improvement.

Recommendations

In the primary research findings, it is clear that there are various aspects of the maintenance activities. The cost implications of the maintenance are high. Respondents feel the need of adopting certain measures to improve the efficiency of the services. The real challenge for the company is to attract and retain highly technical and skilled staff. Some respondents indicate good remuneration and competitive wages to be important factors. Therefore based on the primary research findings and analysis, following recommendations are made: